In fields where precision is non-negotiable, such as aerospace, pharmaceuticals, food manufacturing, and semiconductor production, cleanliness cannot be judged by appearance alone. Even facilities that look pristine may harbor microscopic particles capable of disrupting processes, degrading product quality, and creating compliance issues. Effective contamination control requires a comprehensive strategy that goes far beyond visible surface cleaning.

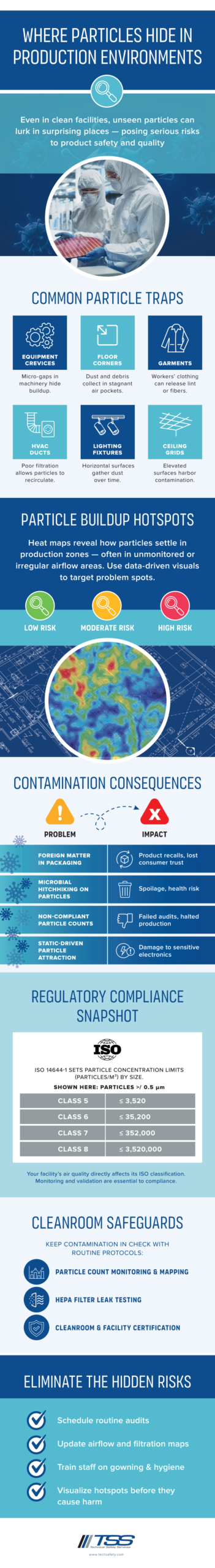

Often-Overlooked Sources of Contamination

Regular sanitation routines and filtered air systems are essential, but they are not sufficient on their own. Mechanical systems naturally degrade over time, releasing particles from components like seals, gaskets, bearings, and metal surfaces. These contaminants frequently remain undetected until they interfere with production outcomes or regulatory standards.

Everyday movement within a facility also contributes to particle spread. Doors opening and closing, equipment transfers, and personnel movement between zones can disturb settled debris and carry it into sensitive areas. Without controlled pathways and movement protocols, even routine activity can introduce risk.

Environmental changes further complicate contamination control. Variations in temperature and humidity can cause condensation to form on ceilings, ductwork, or overhead structures. As moisture evaporates, trapped particles may be released into controlled spaces. Static buildup on plastics and synthetic materials can attract fine particles, which are later dislodged during handling.

Even advanced ventilation systems require close oversight. Inefficient airflow design or infrequent testing can result in stagnant zones where particles quietly accumulate until they are disturbed.

Preventing Contamination Before It Spreads

The most reliable defense against contamination is proactive monitoring. Instead of relying on occasional inspections, facilities benefit from tracking particle levels over time. This data reveals trends and helps identify maintenance activities, equipment changes, or environmental conditions that contribute to contamination increases.

Facility layout and material selection are equally important. Cleanrooms should be constructed with smooth, nonporous surfaces that are easy to clean and resistant to particle buildup. Equipment designed for quick access and straightforward maintenance reduces downtime while limiting contamination risk.

Personnel practices also play a central role. Garments that minimize fiber shedding, combined with consistent gowning procedures, help reduce the amount of contamination introduced by staff. Reinforcing hygiene standards across all teams ensures these practices remain effective.

Maintenance work should always be performed with contamination control in mind. Filter changes, lubrication, and inspections must be carefully planned to avoid disrupting controlled areas. Strong coordination between operations and maintenance teams helps preserve clean zones, even during busy or high-traffic periods.

Building a Forward-Looking Contamination Strategy

Reactive cleaning alone leaves facilities vulnerable. A predictive approach emphasizes understanding particle movement, validating airflow patterns, and maintaining ongoing staff education. This mindset allows organizations to address risks before they affect production.

Even particles that cannot be seen can create costly consequences. Protecting product quality and meeting regulatory expectations requires attention to the full contamination lifecycle, from origin to dispersion. By taking a system-wide approach, facilities can maintain operational efficiency, reduce downtime, and ensure every product leaving the floor meets the highest standards.

For more on this, check out the accompanying resource from Technical Safety Services, a provider of cold storage repair services.